What is a Steam Trap?

During the process of heating, the steam created will condensates back into the water after releasing its energy. In order to maximise the heat energy transfer and ensure the safety of the system, the water (condensates) must be removed. The act of removing condensates without any loss of live steam is the prime function of the steam traps. Additionally, steam traps also discharge air that is present in the system prior to the system start-up to ensure a safer process.

Why do we need Steam Trap?

As mentioned before, the steam created within the boiler will later condensate into the water and clogged within the pipelines. Thus causing a large amount of heat loss within the system. Therefore, the purpose of a steam trap is to allow condensate and air to be discharged from the steam system while preventing the loss of live steam. This special type of valve opens when condensate and air are present and closes when steam tries to pass. Hence ‘trapping’ the steam!

What are the uses for Steam Trap?

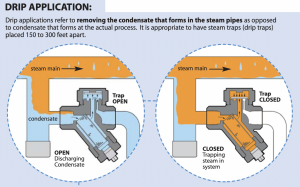

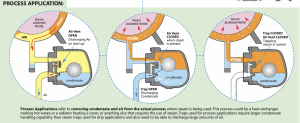

There are two general types of application for steam traps. Drip Application and Process Application.

- Drip Application: This type of applications refers to the process of removing condensate from steam main and steam supply lines as opposed to condensate that forms at the actual process (heat exchanger, jacketed kettle, radiator, etc.). During the period of heating, steam loses some of its heat energy through radiation causes the condensate to form in the pipes. Hence, for safety and efficiency reasons, this condensate has to be removed continuously during the process. The steam traps used for this purpose are usually called Drip Traps. Examples of Drip Traps are Thermodynamic traps, Float, Thermostatic and Inverted Bucket traps. However, for a completely sufficient steam system, drip traps are not entirely relied on when discharging the air from the system. This function is rather relied on by another different type of trap, Process Traps and Air Vents.

reference: www.watsonmcdaniel.com

- Process Application: Process applications refer to removing condensate and air where the actual process using the steam is taking place. This process could be a heat exchanger making hot water, or a radiator heating a room, or anything else that requires the use of steam. Traps used for process applications require larger condensate handling capability in contrast to steam traps that are used for drip applications. Traps used in Process applications also need to be able to discharge large amounts of air present in the system at start-up. The most common trap choice for process applications is Float & Thermostatic traps since they do an excellent job of discharging condensate and air. Thermostatic traps make a good choice for process applications since they also do an excellent job of discharging air and condensate. In contrast, the lack of air venting capability of the Thermodynamic and Inverted Bucket traps, make these trap types a less desirable choice for most process applications.

reference: www.watsonmcdaniel.com

Types of Steam Traps and their functions

1. Thermodynamic Steam Trap

Thermodynamic steam traps have a unique operating principle that relies on the dynamics of water and flashes steam. They are simple, robust and reliable and can operate up to very high temperatures and pressures. Their construction, use and benefits are detailed on this page. Additionally, these steam traps are extremely robust and easy to use. As the flash steam passes through the trap (as shown above), the flat sealing face door will be pushed back and the cool condensate along with some air will be discharged from the inner ring under the disc, and out through the three peripheral outlets. Then the hot condensate will later flow through from the inlet into the chamber under the disc and drops in pressure. Thus releasing flash steam at a high velocity creates a low-pressure area under the disc which draws it towards the seat. Simultaneously, the flash steam’s pressure build-up inside the chamber and force the disc down against the incoming condensate until it sits on the inner and outer rings. During this, the steam is trapped in the upper chamber, and the pressure above the disc is equal to the pressure under the disc. Eventually, the trapped pressure in the upper chamber falls as the flash steam condenses. The disc is raised by the now higher condensate pressure and the cycle repeats.

Suggested Thermodynamic Steam Trap:

2. Bẫy Hơi Phao (Float Steam Trap)

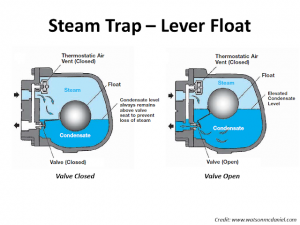

Trong bẫy hơi phao (Float Steam Trap), vị trí của phao bị ảnh hưởng trực tiếp bởi mức độ ngưng tụ trong bẫy. Phao phản ứng với dòng nước ngưng, đóng mở van để bù lại phù hợp.

Trong bẫy hơi phao (Float Steam Trap), vị trí của phao bị ảnh hưởng trực tiếp bởi mức độ ngưng tụ trong bẫy. Phao phản ứng với dòng nước ngưng, đóng mở van để bù lại phù hợp.

- Phao đòn bẩy vs. phao tự do.

Trong thiết kế bẫy hơi phao đòn bẩy, một phao được gắn vào một đòn bẩy điều khiển van. Khi nước ngưng chảy vào bẫy, phao sẽ nổi và di chuyển cần gạt, khiến van bẫy mở ra. Tuy nhiên, do chuyển động hạn chế của tay đòn, đầu van thường nằm trong đường dẫn của dòng nước ngưng, điều này có thể dẫn đến một lực kéo phụ tác động làm đóng van trong điều kiện dòng chảy cao.

Các Mặt Hàng Bẫy Hơi Phao (Float Steam Trap) Tiêu Biểu:

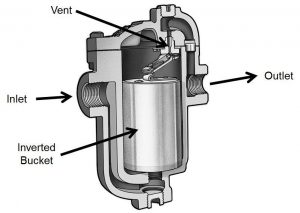

3. Bẫy hơi gầu đảo (Inverted Bucket Steam Trap)

Trong bẫy hơi gầu đảo (inverted bucket steam trap), gầu bên trong bẫy được gắn vào một đòn bẩy để mở và đóng van bẫy theo chuyển động của gầu. Khi hơi nước hoặc không khí chảy vào bên dưới của xô ngược và nước ngưng tụ bao quanh nó ở bên ngoài, hơi nước làm cho gầu nổi và bốc lên. Ở vị trí này, gầu sẽ làm cho van bẫy đóng lại. Có một lỗ thông hơi trên đỉnh của gầu cho phép một lượng nhỏ hơi được thoát ra trên đỉnh của bẫy, nơi nó được xả xuống hạ lưu. Khi hơi thoát ra ngoài qua lỗ thông hơi, nước ngưng bắt đầu lấp đầy bên trong thùng, khiến nó chìm xuống và cho phép cần gạt mở van bẫy và xả nước ngưng (cùng với bất kỳ hơi nào bị giữ trong bẫy).